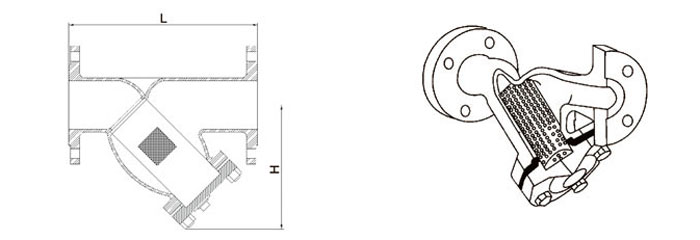

Y Type Strainers are constructed from rugged castings that are machined to exacting specifications. These bodies have drilled flanges that are in accordance with ASME B16.1. Alternatively to EN, DIN, BS or JIS Standards.

Y Strainer features a machined groove in both the body and cover for proper screen alignment and to ensure accurate reseating when servicing is required. The gasket is a synthetic fiber that is compressed between the body and cover for maximum strength and durability. Upon request, The Y Type strainers can be furnished with a blow-off plug. Standard perforated 304 stainless steel screens are furnished for a maximum strength. Different size perforations and meshes are available in stainless steel, monel, and brass to meet specific media requirements. If the media is not indicated, screens for water will be supplied. Self cleaning is accomplished by opening the valve or drain plug connected to the blow-off port.

Cast Y Strainer take their name from their configuration. They are most commonly used in pressurized lines, gas or liquid, but can also be used in suction or vacauum conditions. They are intended for application where small amounts of solid e are expected and where clean-out will be infrequent. If solids will flush easily from the screen, and fluid can be exhausted to atmosphere, a blow down valve on the drain port will allow clean-out without removal of screen, and without interrupting the process flow.

» Manufactured under ISO 9001:2008 Management System

»Size Ranges: 1 1/2" through 24"

Pressure Ratings: ANSI #150 to 2500, PN16~PN420

» Standards compliance: ASME B16.34, DIN 3202, ASME B16.10, MSS SP-71, BS EN558, ASME B16.1 CLASS 125, ASME B16.5 CL150, EN1092, EN12226, ISO 5208, API 598 or equivalents

» Materials: Cast Iron, Ductile Iron, Cast Carbon Steel, Cast Stainless Steel, Cast Duplex or Other Specials Ends Connections: Flanged(FF, RF, RTJ) to international standards

» Screen: Stainless Steel, Gr. 304 or 316

» Fusion Bonded Epoxy Coating »Threaded Drain Plug Device