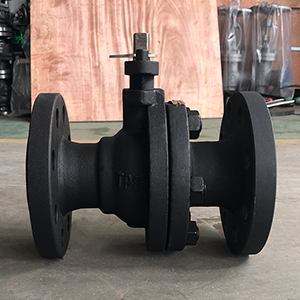

Cast Steel Floating Ball Valve

ProductRange

Size: 1/2" - 10" (DN15 - DN250)

Class: 150LB, 300LB (PN1.6 - PN4.0)

Body Material: A216 WCB/ WCC, A352 LCB/ LCC, A351 CF8/ CF3/ CF8M/ CF3M, A890 4A/ 5A...

Trim Material: A105+ENP, 13CR, SS304/ SS316, F304/ F316...

Seat & Seals: PTFE, R-PTFE, NYLON, DEVLON, PEEK...or Metal Sealing

Operation: Lever/ Wrench, Gear, Pneumatic/ Electic Actuator...

Standard Information

Design Basis: API 6D/ BS 5351(ISO 17292)/ ASME B16.34/ API 608...

Face-to-Face Dimension: ASME B16.10...

Flanged End: ASME B16.5

Butt-Welding End: ASME B16.25

Socket Welding End: ASME B16.11

Wall Thickness: ASME B16.34

Firesafe: API607, API 6FA

Inspection and Test: API 6D/ API 598/ BS 6755...

Valve Details

|

1. Full Bore Design Two piece construction; This structure is more convenient for disassembly valve disassembly and internal parts maintenance replacement. Full-bore design provides big flow control. |

|

|

2. Bolted Bonnet Connection We used Teflon Xylon PTFE A193 B7/A194 2H, which is anti-rusting specially used for seawater and so on. |

|

3. Flange Face End The Raised Face is based on ASME B16.5 standard requirements, with specific roughness requirements, ensuring that the surface is both flexible and provides high-quality sealing. |

Applications

Petrochemical Industry, Oil Fields, Metallurgy, Coal Chemical Industry, Power Station, Solar Energy Industry, Paper Making Industry, Pharmacy Industry, Mining Industry etc.

Contact

Zhejiang Tiansheng Valve Co., Ltdis a leading valve manufacture in the supply of valves, piping and flanges.

As API 6D, CE, ISO certified valve manufatuer, our products cover gate/globe/ball/butterfly/check valves/strainers and etc.with

carbon steel, stainless steel, brass, bronze and some specialmateial.

We take quality as the life, cost as the base, service as line, providing the best products and pipeline solution to new or old customers, adhering to the development concept of “Bright Future, Scientific Development”, to keep pioneering and innovation

Contact us freely if you have more question!